We create unique skis for any condition using proven technologies inspired by racing, utilizing only the finest raw materials. Sophisticated constructions and patented technologies developed in Austria create new benchmarks in performance standards.

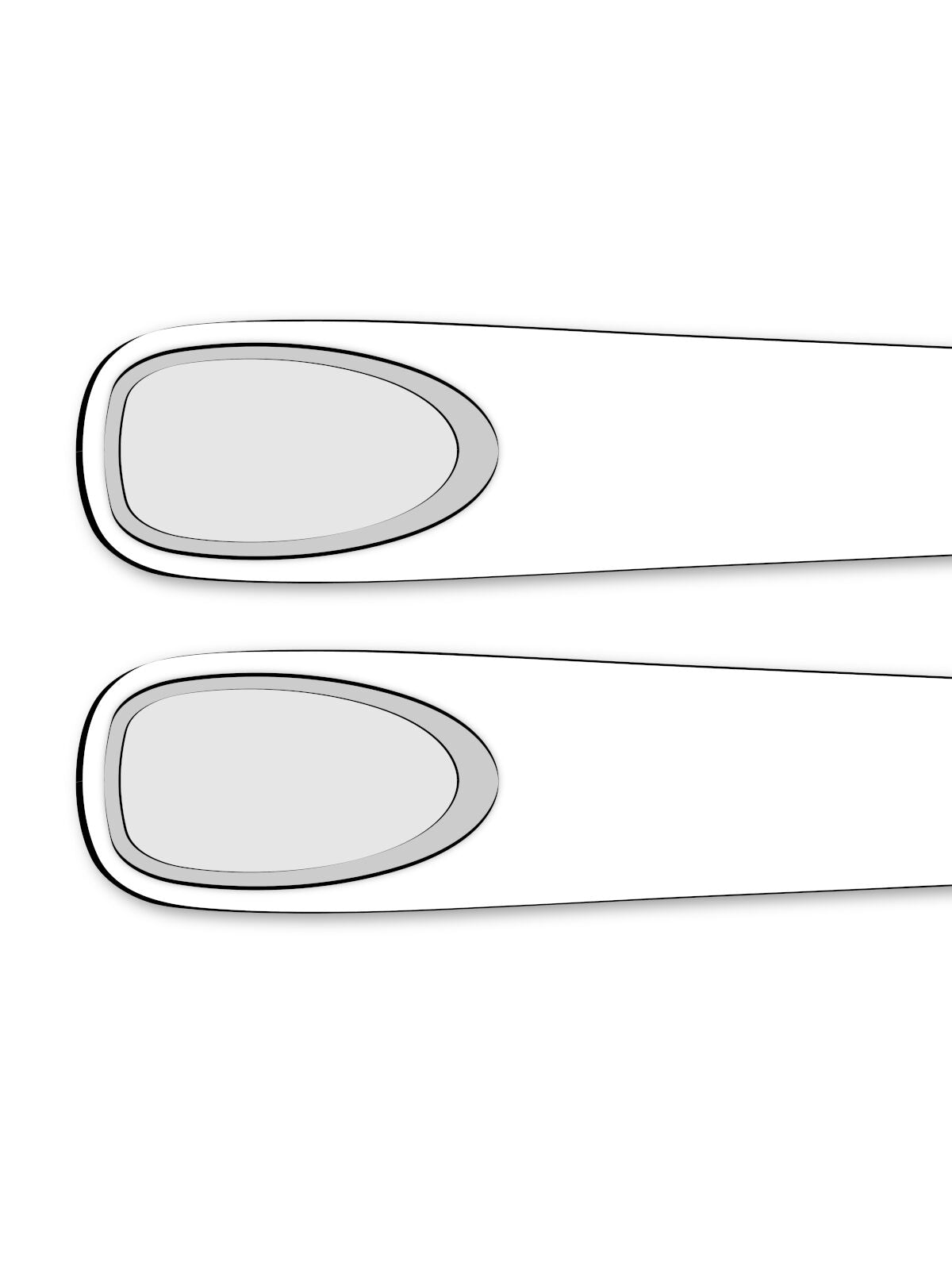

HOLLOWTECH

Our patented, key technology is unique to ski manufacturing. By removing unneeded layers in the front of the ski we make the ski lighter. This results in several advantages:

- Reduction of ski tip vibration (up to 30%)

- More stability

- Optimized edge grip

- Better steering precision

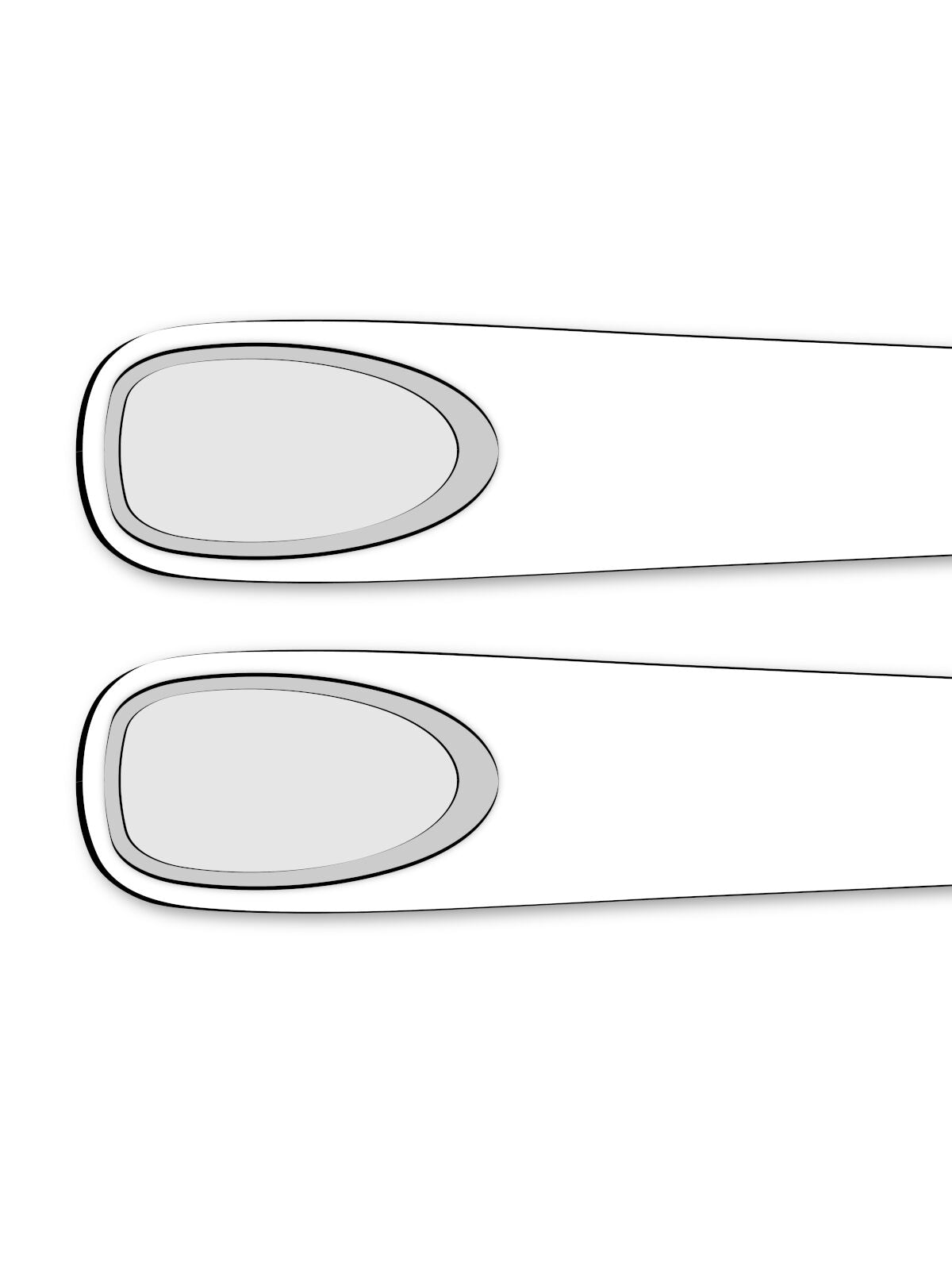

The new, revolutionized HOLLOWTECH 3.0 has a two-tier construction: a new outer ring cuts out even more material and therefore even more weight. The size of the HOLLOWTECH is always precisely matched to the shovel of each particular model - for performance that's truly unbeatable.

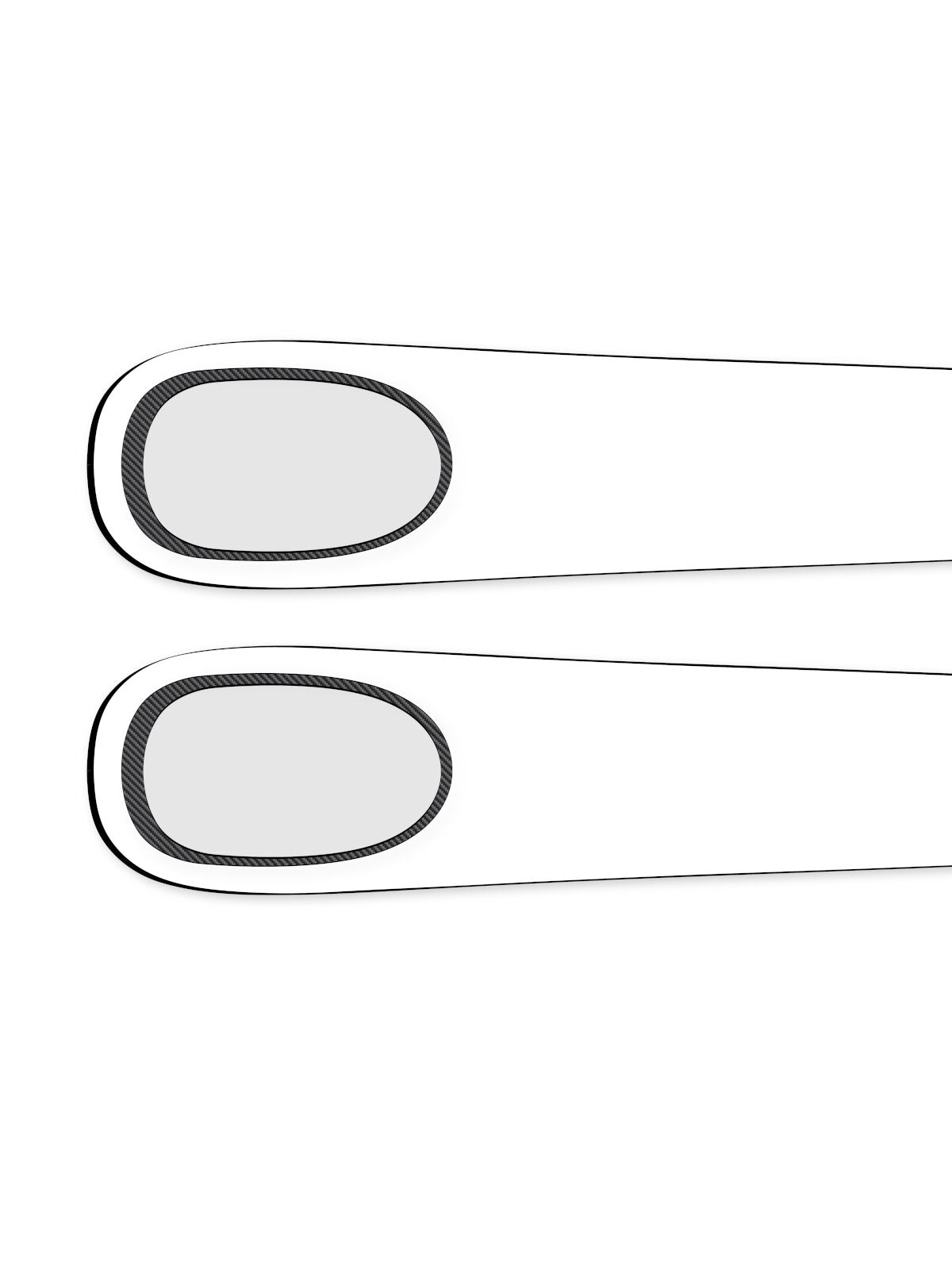

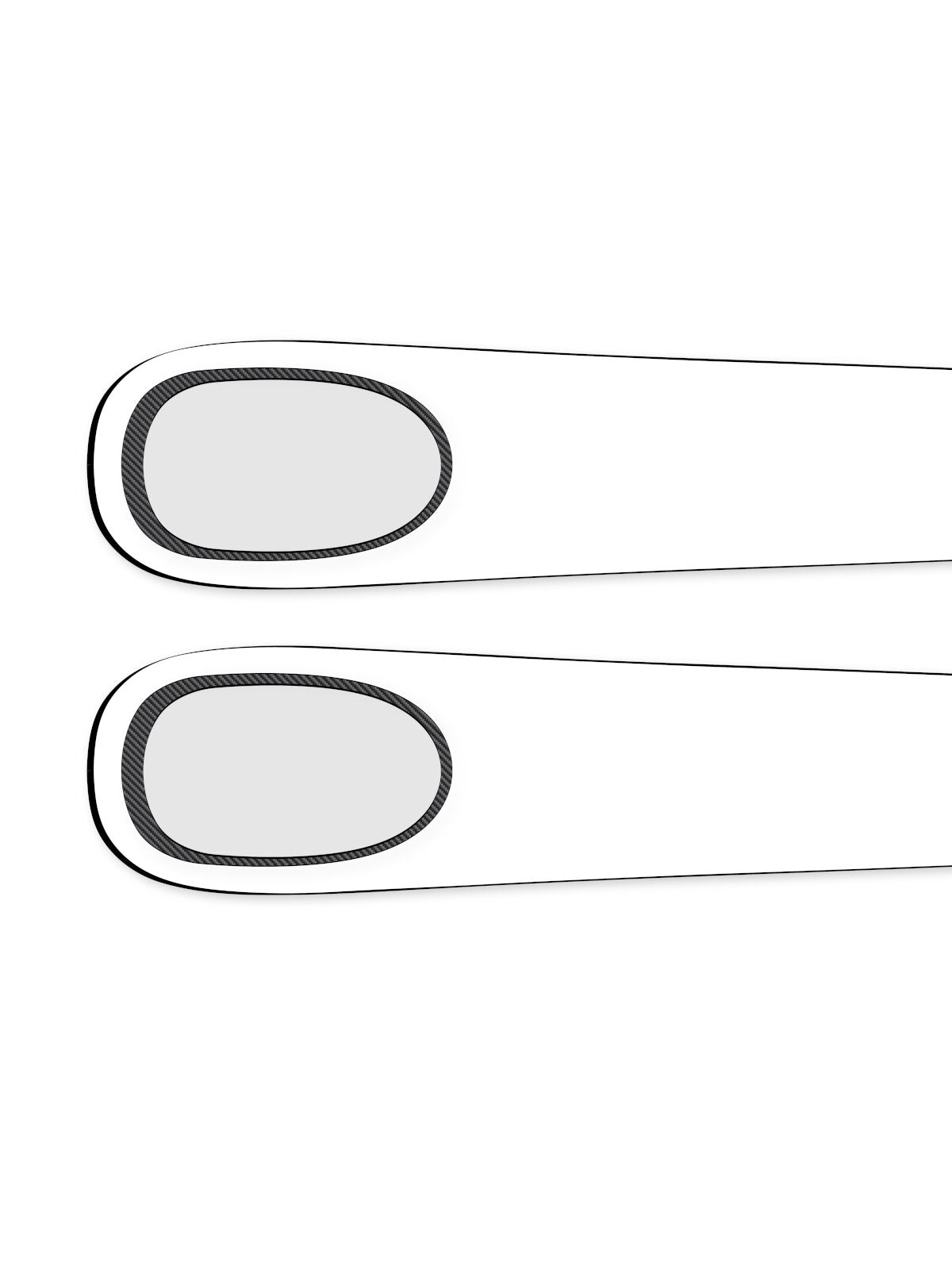

Thanks to a carbon layer in the shovel, the entire construction is even more stable and lighter. The Hollowtech 3.0 Carbon convinces with its strong damping properties and is used exclusively in the MX model line.

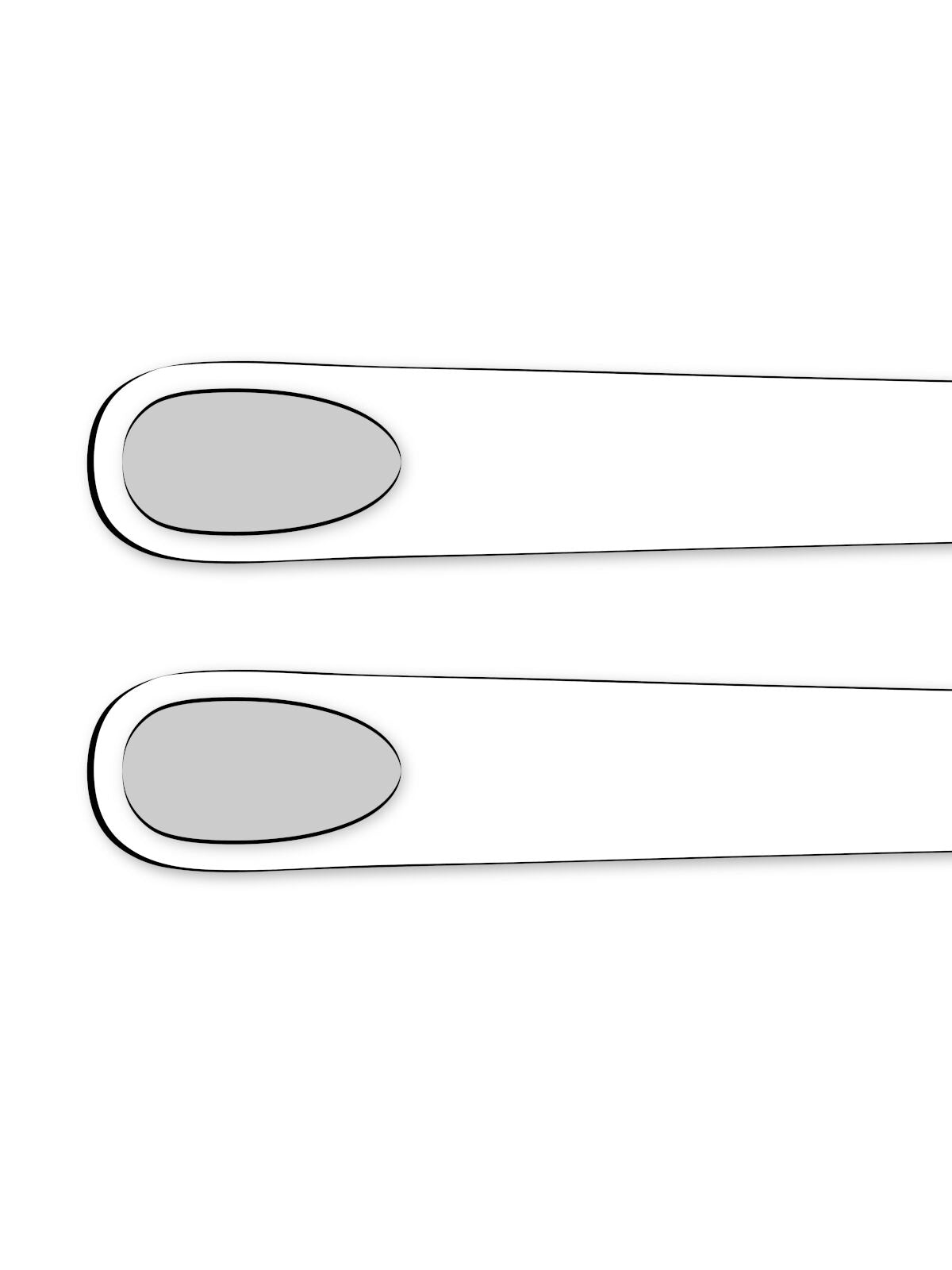

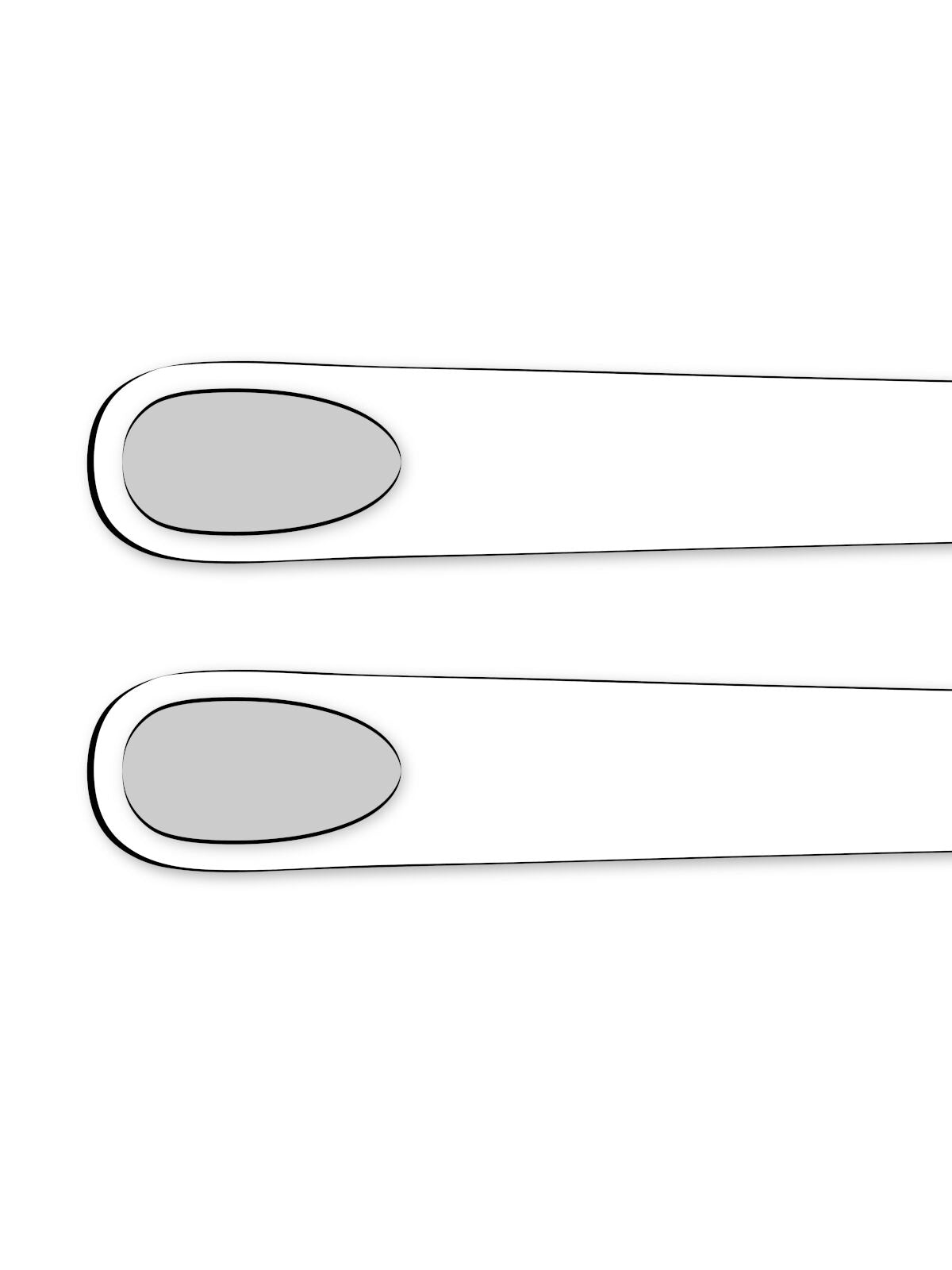

Especially for our high-performance piste models and racing skis, we have further developed the Hollowtech 2.0. Even larger than before, it ensures greater stability, even at top speeds in the World Cup.

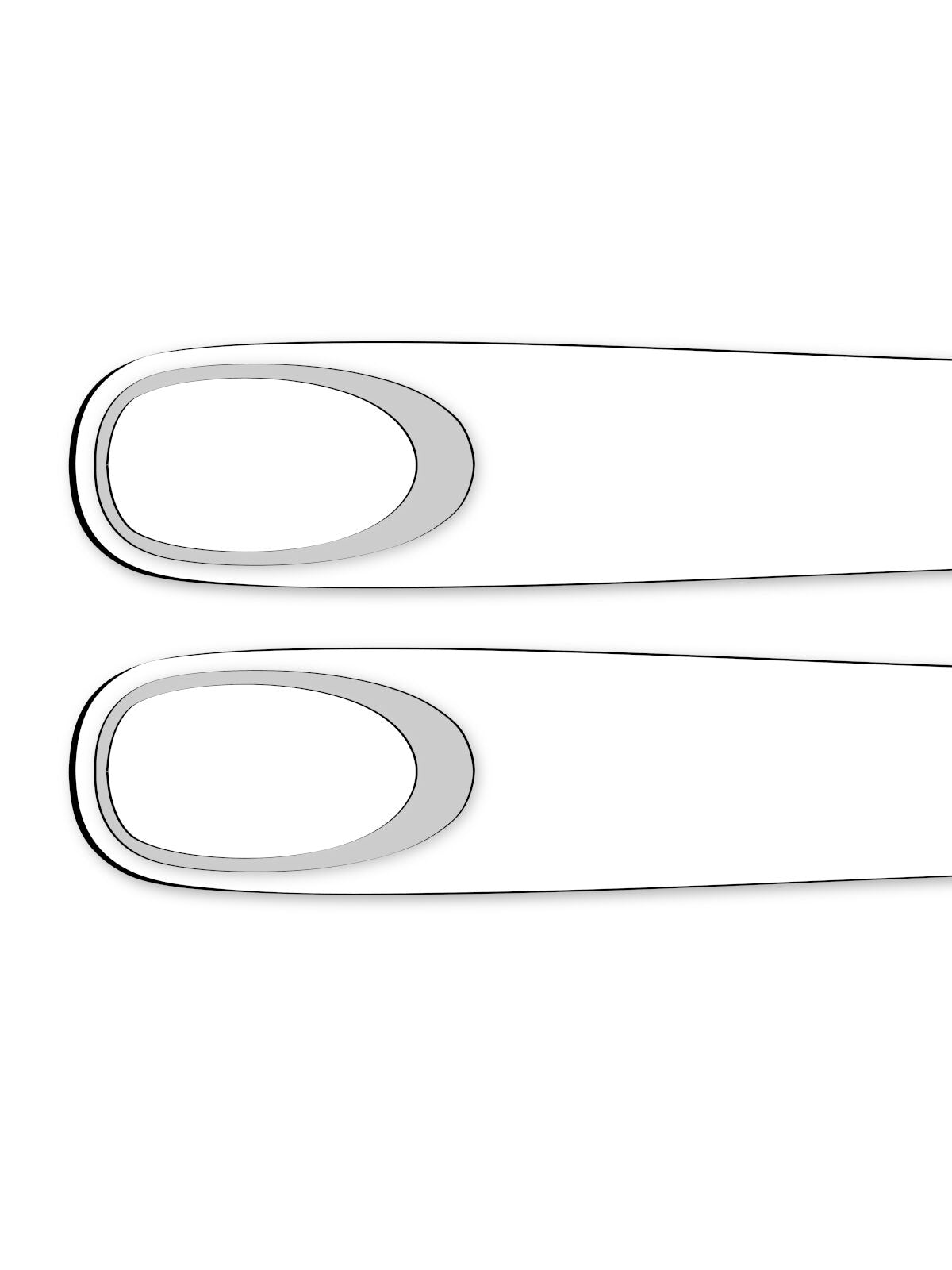

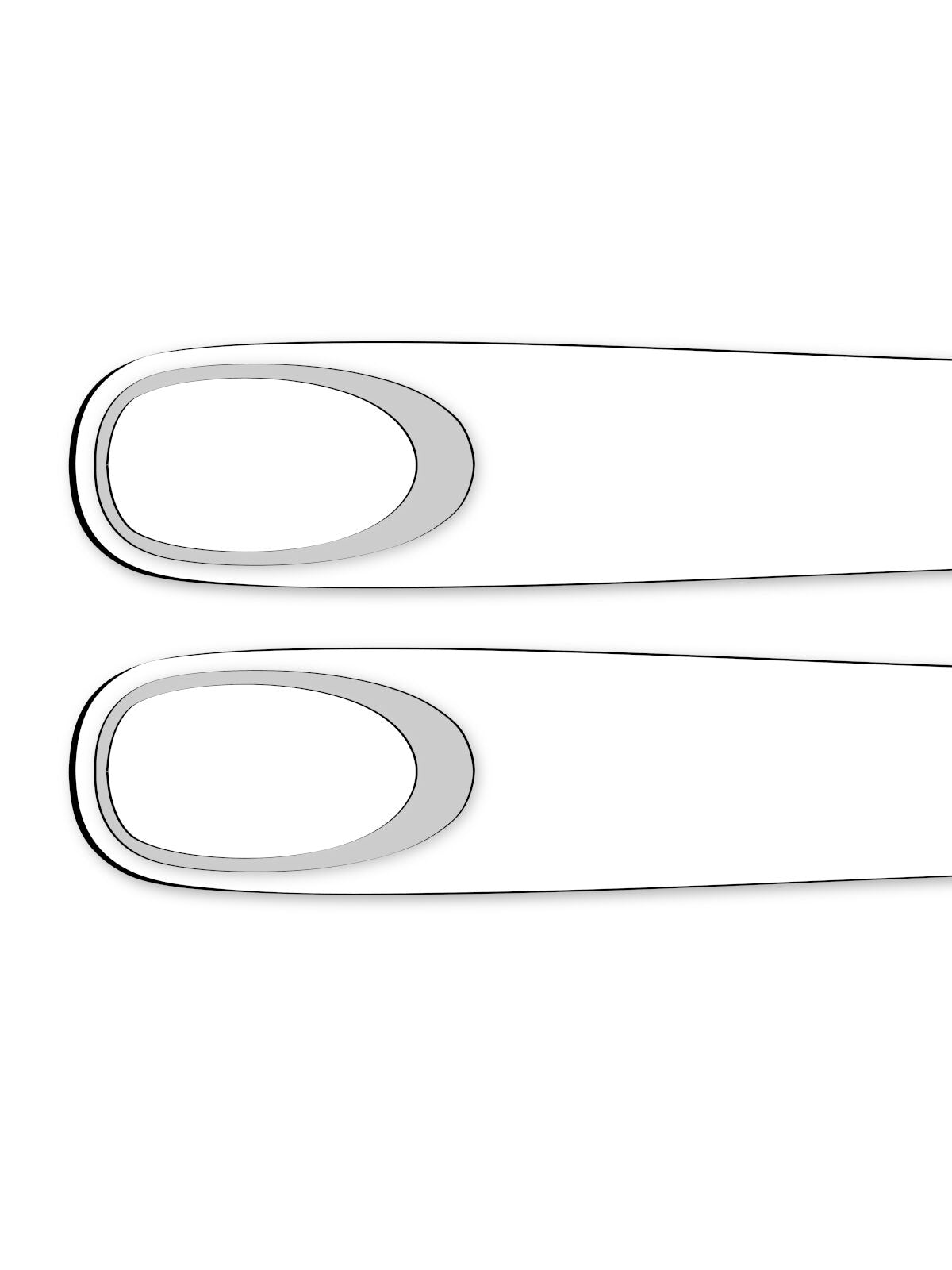

Featured exclusively in the TX range, the HOLLOWTECH is highlighted with a luminous material, creating a glow-in-the-dark effect.

The new, revolutionized HOLLOWTECH 3.0 has a two-tier construction: a new outer ring cuts out even more material and therefore even more weight. The size of the HOLLOWTECH is always precisely matched to the shovel of each particular model - for performance that's truly unbeatable.

Thanks to a carbon layer in the shovel, the entire construction is even more stable and lighter. The Hollowtech 3.0 Carbon convinces with its strong damping properties and is used exclusively in the MX model line.

Especially for our high-performance piste models and racing skis, we have further developed the Hollowtech 2.0. Even larger than before, it ensures greater stability, even at top speeds in the World Cup.

Featured exclusively in the TX range, the HOLLOWTECH is highlighted with a luminous material, creating a glow-in-the-dark effect.

HOLLOWTECH EXPLAINED

WOODCORE

Each Kästle ski is built with the finest woodcore, manufactured with precision to one-tenth of a millimeter. This allows us to control the weight, responsiveness and dampening characteristics of the ski, resulting in a high-quality, durable product.

70%

local wood in ski production

The choice of wood is determined by the desired properties of the ski in terms of stiffness, grip, stability, and weight. If the final product is to be stable, we choose a wood with a higher density, such as poplar or beech. A ski that should convince its rider with lightness and float, usually contains a lighter wood, such as paulownia. In many cases, however, we use a combination of different types of wood to meet all requirements. These are glued together and only then pressed with the remaining layers.

But why wood anyway? No other substance can provide the ski with the desired handling characteristics as well as this material - and retain them over a longer period of time. It is quite simply THE quality feature, which is why not only every Kästle has a wood core, but special attention is paid to its origin in the selection as well. Thus, we use up to almost 80% domestic woods, whose main supplier is located in Switzerland.

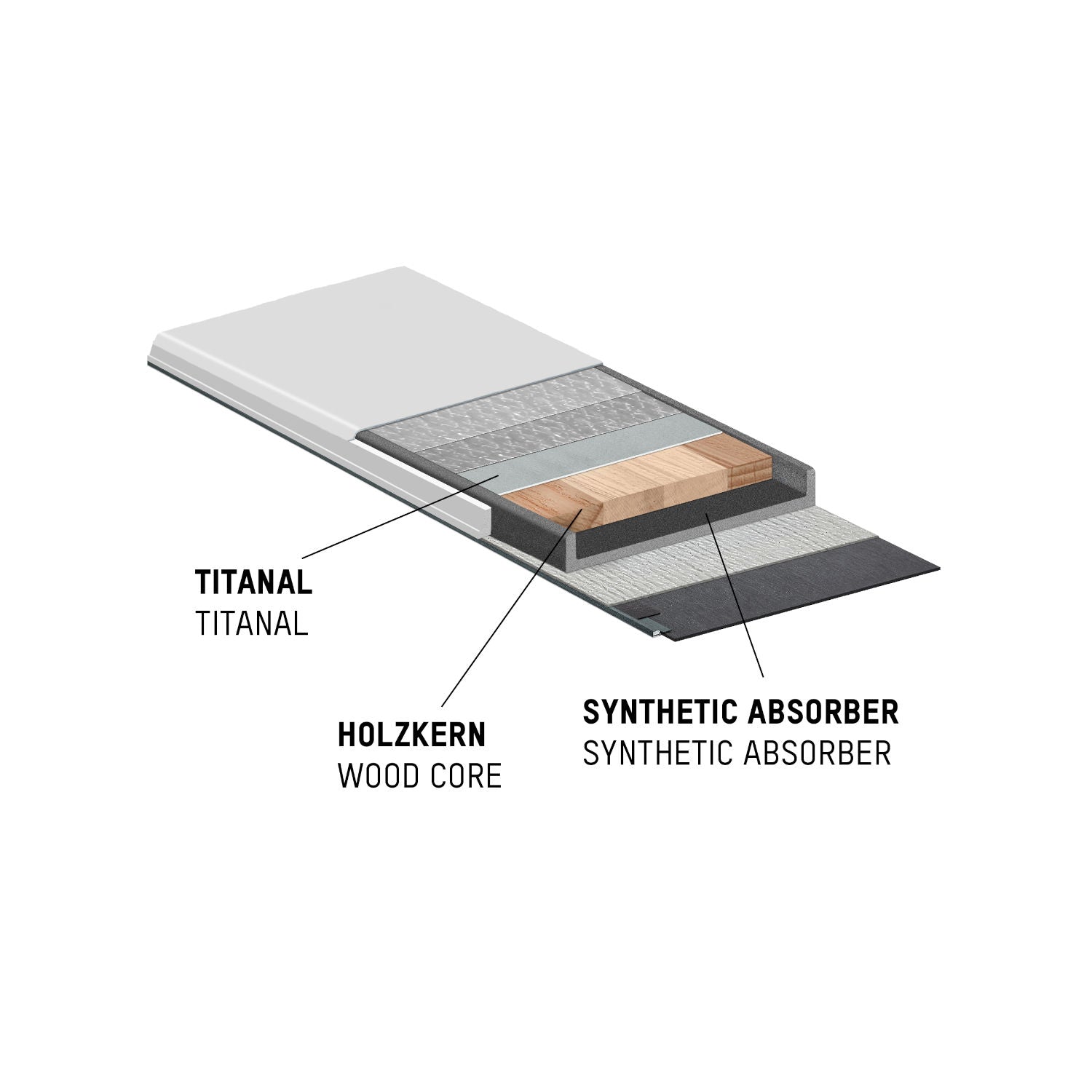

SYMBIO CORE

The new Kästle SYMBIO CORE blends 3 materials into one symbiosis:

TITANAL top-layer gives the ski its stability

CENTRAL WOOD CORE ensures the familiar performance and durability

SYNTHETIC ABSORBER material rounds off the ski‘s properties by making it 20% lighter at equal performance, compared to previous models without Symbio Core.

OTHER MATERIALS

To be able to further vary the riding characteristics of our skis, additional titanal, carbon or fiberglass inserts are used.

Titanal

Titanal promises damping, stability and optimal power transmission. So it's no surprise that we use this material in a large number of our skis, since Kästle stands for maximum smoothness at high speeds.

Carbon

is one of the most multifaceted materials. Exceptionally resilient and with the lowest weight, it is extremely interesting for ski construction. We use it mainly for our touring skis.

Glass fiber

Glass fiber is characterized by its high elasticity. Usually this material is used together with carbon inserts to achieve the perfect combination of stability and flexibility.

Base

The base, as the coating of the running surface, is another essential component of our skis and is largely responsible for their gliding properties. In our skis we mainly use a fast racing base, which consists of over 35% recycled material.

Topsheets

Kästle topsheets are made of special TPU or polyamide. For products that need to be a bit more robust - such as our freeriders or children's skis - we use a corundum protective surface.

Titanal promises damping, stability and optimal power transmission. So it's no surprise that we use this material in a large number of our skis, since Kästle stands for maximum smoothness at high speeds.

is one of the most multifaceted materials. Exceptionally resilient and with the lowest weight, it is extremely interesting for ski construction. We use it mainly for our touring skis.

Glass fiber is characterized by its high elasticity. Usually this material is used together with carbon inserts to achieve the perfect combination of stability and flexibility.

The base, as the coating of the running surface, is another essential component of our skis and is largely responsible for their gliding properties. In our skis we mainly use a fast racing base, which consists of over 35% recycled material.

Kästle topsheets are made of special TPU or polyamide. For products that need to be a bit more robust - such as our freeriders or children's skis - we use a corundum protective surface.

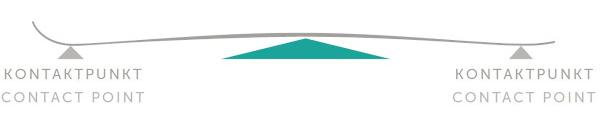

CAMBER

We build our skis with classic camber and distinguish between Standard Camber and Low Camber.

STANDARD CAMBER

With Sandard Camber, the ski center is clearly elevated and the contact points to the snow are far forward and back. The effective edge is longer and the ski initiates turns more quickly and precisely.

LOW CAMBER

With Low Camber, the ski center is slightly elevated and the contact points are moved toward the ski center. The effective edge is consequentially less, and the ski is more playful and forgiving.